As the global demand for efficient and secure agricultural storage continues to rise, BEN-THOMAS, a premier name in specialized metal forming technology, has announced the launch of its next-generation Grain Bin Silo Wall Roll Forming Lines.

As the global demand for efficient and secure agricultural storage continues to rise, BEN-THOMAS, a premier name in specialized metal forming technology, has announced the launch of its next-generation Grain Bin Silo Wall Roll Forming Lines.

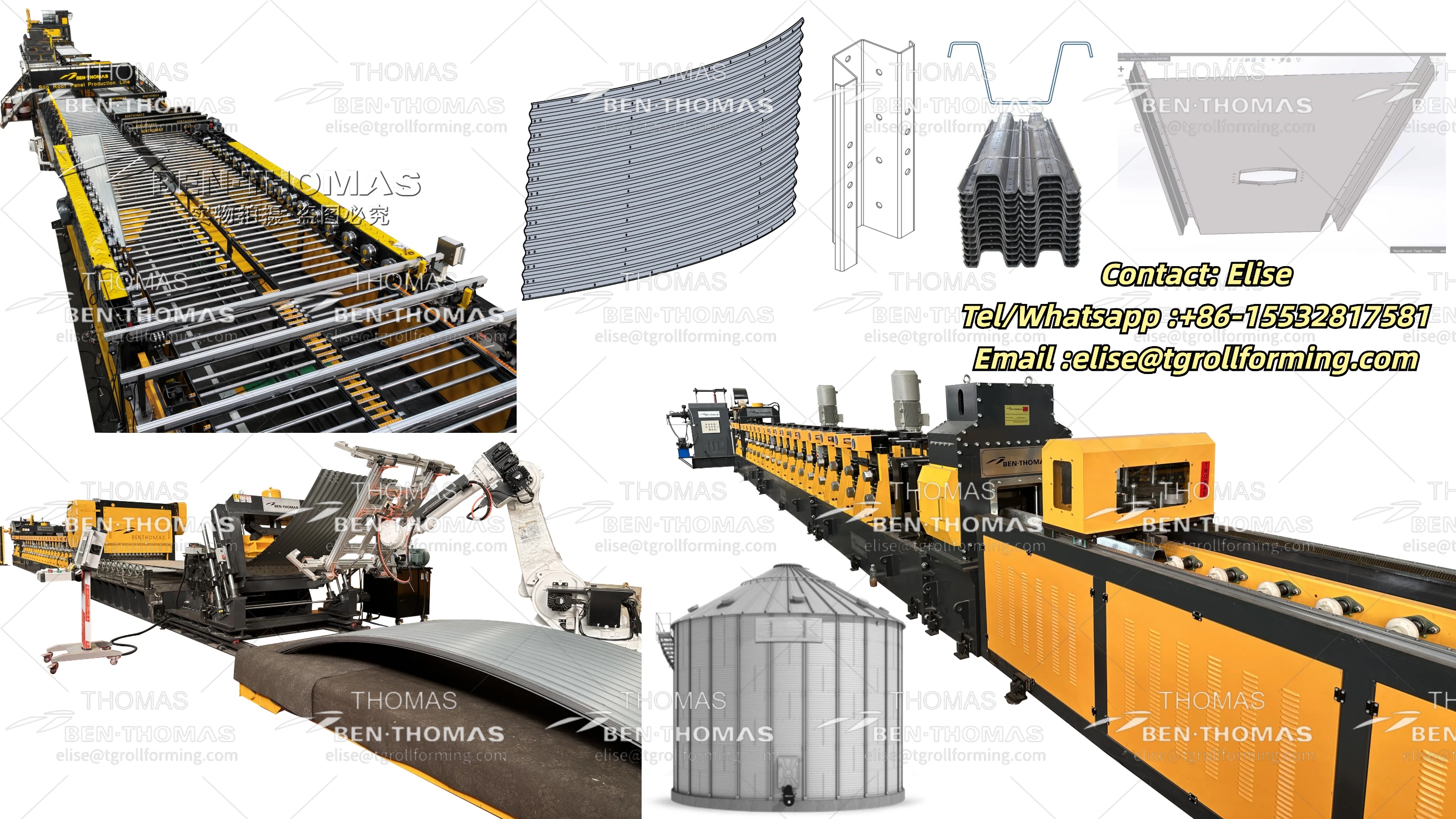

Under the flagship Thomas Roll Former series, the company is introducing state-of-the-art technology specifically engineered to elevate the production standards of corrugated grain silos. This new grain bin silo line of machinery is designed to help manufacturers achieve maximum output with unparalleled structural integrity.

Elevate Your Grain Bin Production with Thomas Roll Former

In the competitive grain storage market, precision is the difference between a silo that lasts decades and one that fails under pressure. The Thomas Gain Bin Roll Former provides a customized solution that addresses the complex requirements of silo wall manufacturing, including high-tensile material handling and precise corrugation consistency.

“Our mission has always been to provide equipment that doesn\’t just work, but optimizes the entire production lifecycle,” said the Lead Engineer at BEN-THOMAS. “By integrating smart automation with heavy-duty mechanical engineering, our grain bin lines are helping our clients produce grain bins that meet the world’s most stringent safety and quality standards.”

State-of-the-Art Features of the BEN-THOMAS Grain bin silo manufacturing line

The BEN-THOMAS Grain Bin Roll Forming Line is built on three core pillars of modern manufacturing:

- Maximum Efficiency: Equipped with high-speed automated feeding and precision punching systems, the line significantly reduces cycle times compared to traditional forming methods.

- Customized Solutions: Recognizing that no two projects are identical, BEN-THOMAS offers tailorable configurations to accommodate different silo diameters, wall thicknesses, and corrugation profiles.

- Superior Quality Control: The system utilizes advanced sensor technology to monitor the rolling process in real-time, ensuring every panel features perfect curvature and hole alignment for easy on-site assembly.

Optimizing the Production Process

Beyond the hardware, BEN-THOMAS focuses on the optimization of the production process. The system is designed for ease of use, featuring an intuitive HMI (Human-Machine Interface) that allows operators to switch between different specifications with minimal downtime. This flexibility makes it an ideal investment for both established manufacturers and those looking to scale their operations.

By choosing the Thomas grain bin silo structure production line, companies are not just buying a machine; they are investing in a decades-long legacy of R&D and a commitment to agricultural infrastructure excellence.

For more details of the silo production lines, please contact with our sales department

Contact: Elise

Tel: +86-155 3281 7581

Email : elise@tgrfm.cn

Post time: Sep-20-2025